From spectral analysis to leak testing

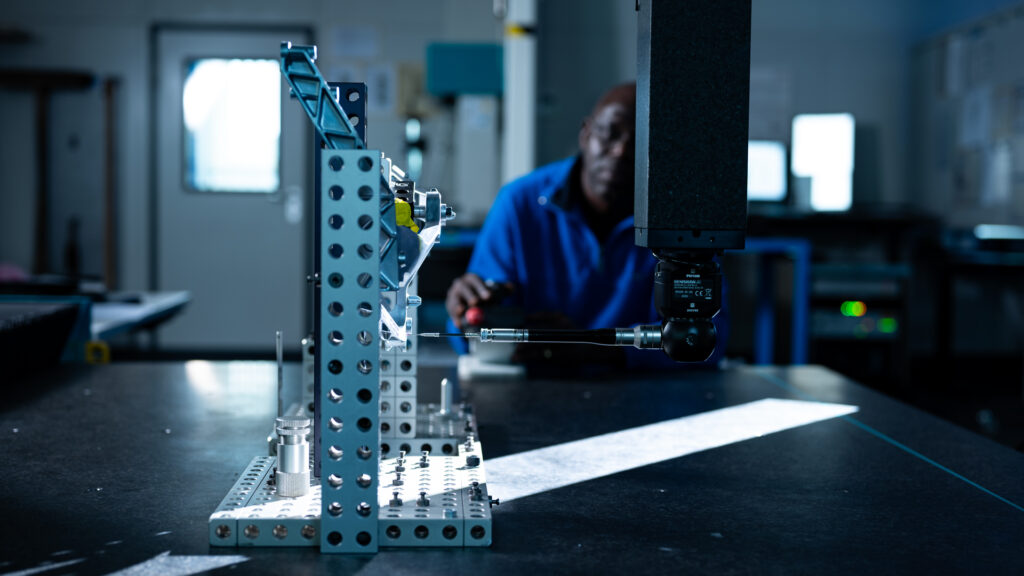

Our quality management encompasses a broad spectrum of modern measurement and monitoring methods.

This begins with spectral analysis of the aluminum ingots supplied, continues with constant monitoring of the machines, and extends to X-ray testing and measurement of the components during production.

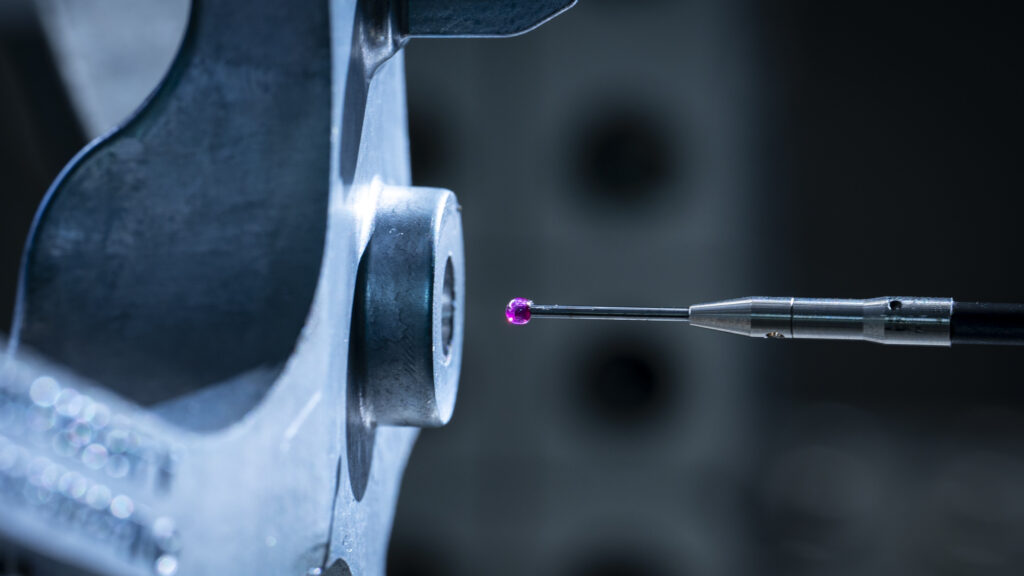

Depending on requirements and specifications, our products undergo various testing procedures, ranging from high-precision 3D coordinate measurements and leak testing to laboratory tests such as micrograph analysis, structural examinations, and the determination of mechanical properties based on tensile and bending tests. This enables us to ensure maximum dimensional accuracy, process reliability, and product quality in accordance with customer specifications at all times.

Our testing procedures at a glance

- 3D digitization

- 3D coordinate measuring machines

- X-ray examination

- Spectral analysis

- Tensile and bending tests

- Structure analysis using microscopy

- Polished section analysis

| Overview of measuring equipment in quality management & materials testing laboratory | 0.06 MB |