Aluminum melt – precision from the ground up

Our aluminum melt forms the basis for high-quality die-cast parts. Using state-of-the-art melting and treatment technologies, we guarantee consistently high metal quality, optimal flow properties, and minimal inclusion defects.

We process up to 7,000 tons of aluminum per year in our melting furnaces. In the melting process, we lay the foundation for precise, durable, and resilient castings.

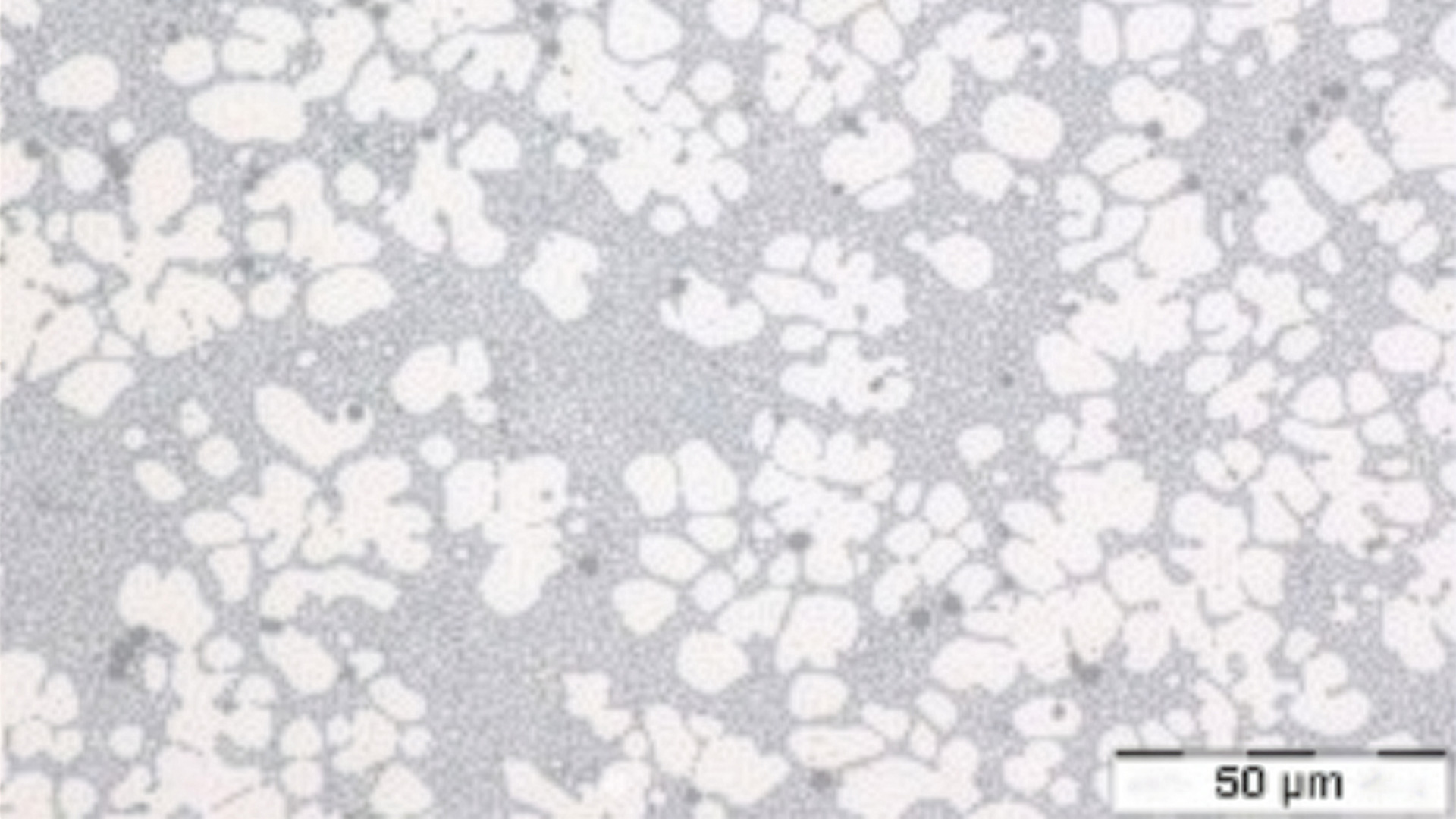

We use the impeller process to effectively clean our molten aluminum of inclusions, gases, and oxides. Through the targeted addition of cleaning agents, the process ensures a homogeneous melt, optimal flow properties, and consistently high metal quality.

The result is castings with excellent density, surface quality, and structural integrity.