State-of-the-art machines for maximum precision – Fritz Schmidt’s machine park

The production facilities of Fritz Schmidt Metallgießerei GmbH & Co. KG cover an area of 27,000 m².

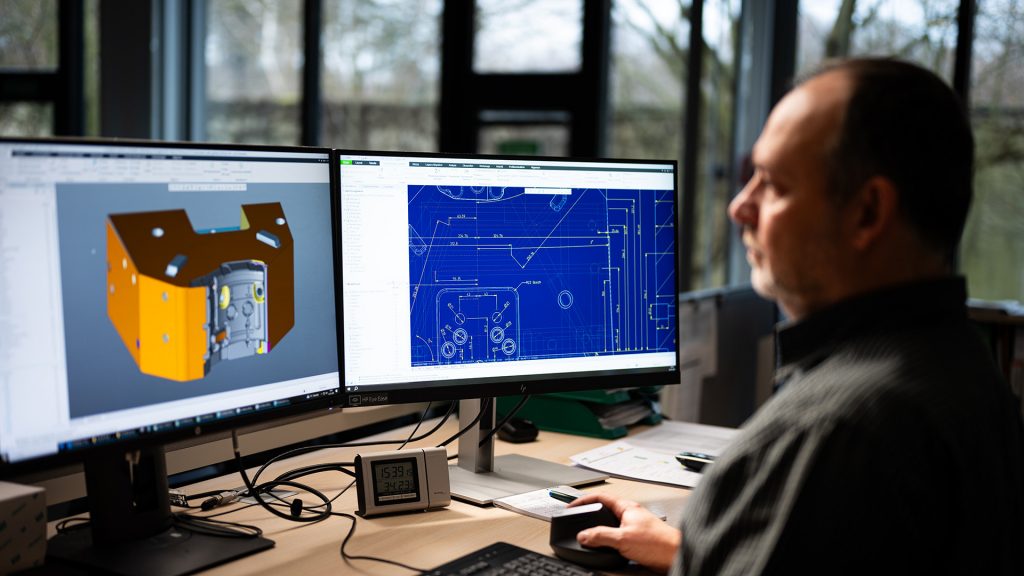

Design & Toolmaking

Our design department is the link between your casting concept and our production. At our 4 CAD workstations and our casting simulation workstation, our designers transform your concepts into die casting molds for series production. Toolmaking is one of our core competencies. 9 CNC milling centers with up to 5-axis milling enable us to manufacture even complex molds with a very high degree of precision.

More about design and toolmakingMelting Plants

The 5 melting furnaces from renowned manufacturers offer a capacity of 1.5 to 10 tons. They can melt several tons of aluminum per hour. This is followed by a cleaning process in our impeller systems.

To the melting plants

The heart of our production

17 die casting machines with a clamping force range between 500 tons and 4,400 tons enable the production of various components in a wide range of sizes.

Details on die casting| Overview of our die casting machines | 0.06 MB |

Deburring Processes

After casting, the components are processed by grinding and cleaning to remove burrs and create a uniform surface. The 13 grinding workstations ensure optimum surface quality and the best possible preparation for subsequent coating. Technical surfaces are produced using 2 blasting and 2 vibratory grinding machines, among other equipment.

Mechanical processing

In mechanical processing, we manufacture components to the highest precision standards. At our 32 CNC centers, we are able to machine components of all sizes.

More about mechanical processing

| Overview of mechanical processing | 0.06 MB |

Further processing

During further processing, our components are assembled according to customer requirements, cleaned at 2 washing stations, and, if necessary, subjected to a 100% leak test. This enables us to guarantee maximum functional reliability and operational readiness.

More information