Aluminum die casting production in Meckenheim

In addition to the expertise customary in the industry, Fritz Schmidt Metallgießerei GmbH & Co. KG also has its own in-house toolmaking facility. Thanks to our high level of vertical integration, we are able to turn our customers’ wishes into reality.

- Close cooperation between designers and project managers with customers

- Mold making, foundry, further processing, and quality assurance

- Precise coordination of sampling dates, high adherence to deadlines guaranteed

- Short response times for tool changes

- Fast tool repair and production reliability

With state-of-the-art machinery, we lay the foundation for precise and efficient production. Modern die casting cells, energy-efficient melting technology, and cutting-edge CNC machining ensure perfect component quality. From small series to large-scale production, we can consistently guarantee the highest quality standards and excellent delivery reliability.

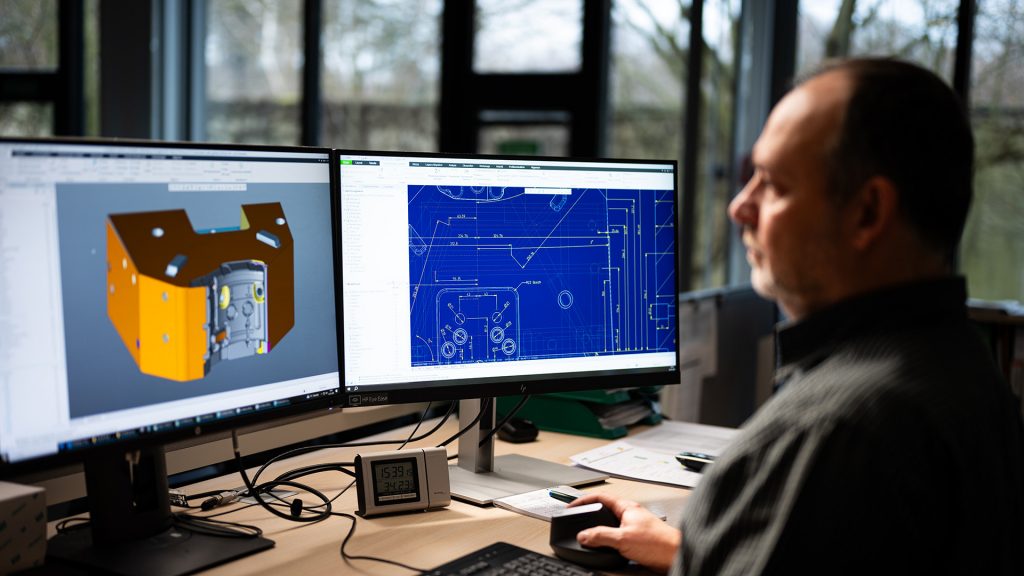

Our machineryOur expertise in design and toolmaking forms the basis for high-quality aluminum die-cast parts. We develop customer-specific tools using modern CAD/CAM systems and rely on precise simulations to ensure optimal casting processes. Our in-house toolmaking facility enables short lead times, high flexibility, and consistently high tool quality.

Design & mold making

The basis for high-quality die casting – with state-of-the-art melting and treatment technologies, we guarantee consistently high metal quality, optimal flow properties, and minimal inclusion defects.

Smelting

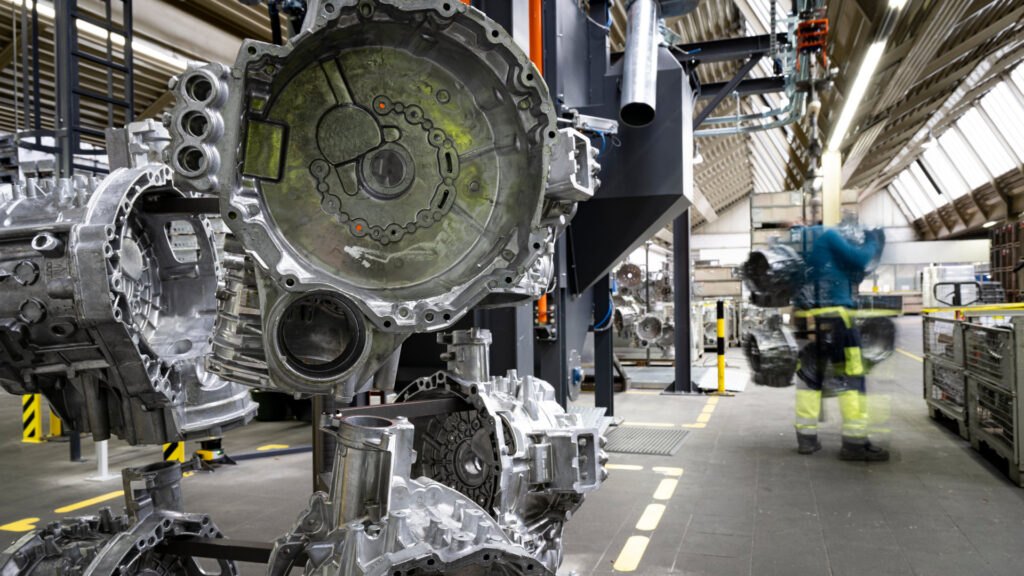

With clamping forces ranging from 500 to 4,400 tons and products weighing from 0.2 kg to 50 kg, our die casting sets standards in precision and quality.

Learn more about our die castingWe use various methods for finishing castings in order to achieve the desired geometric properties and surface finishes.

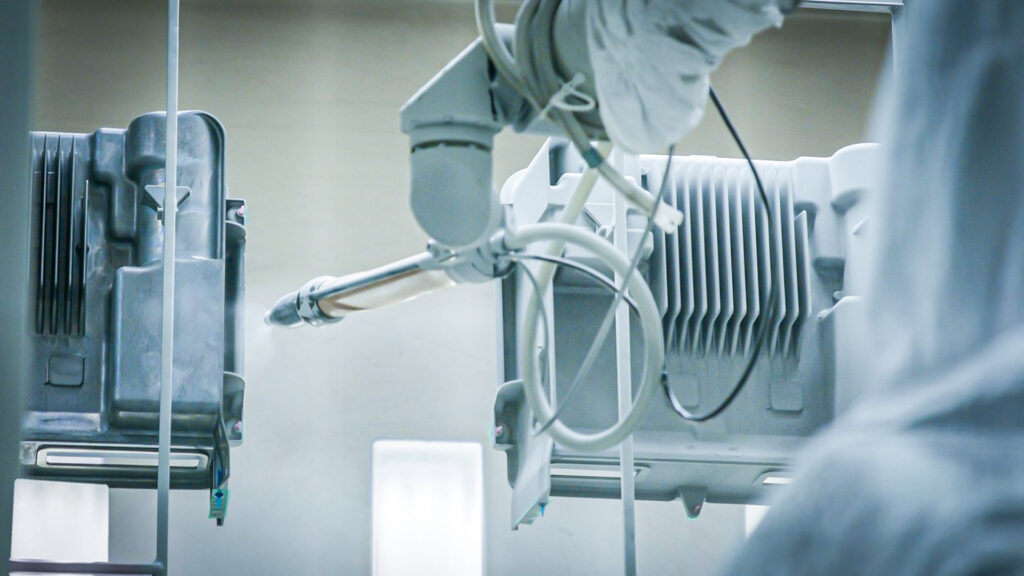

Mechanical processingDepending on customer requirements, we offer a wide range of further processing options for our castings. In addition to simple punch deburring, this also includes surface treatment by vibratory grinding or blasting, as well as manual and machine processing.

Further processing

Whether coatings or assembly processes – together with our service providers, we offer a wide range of additional services.

Learn more