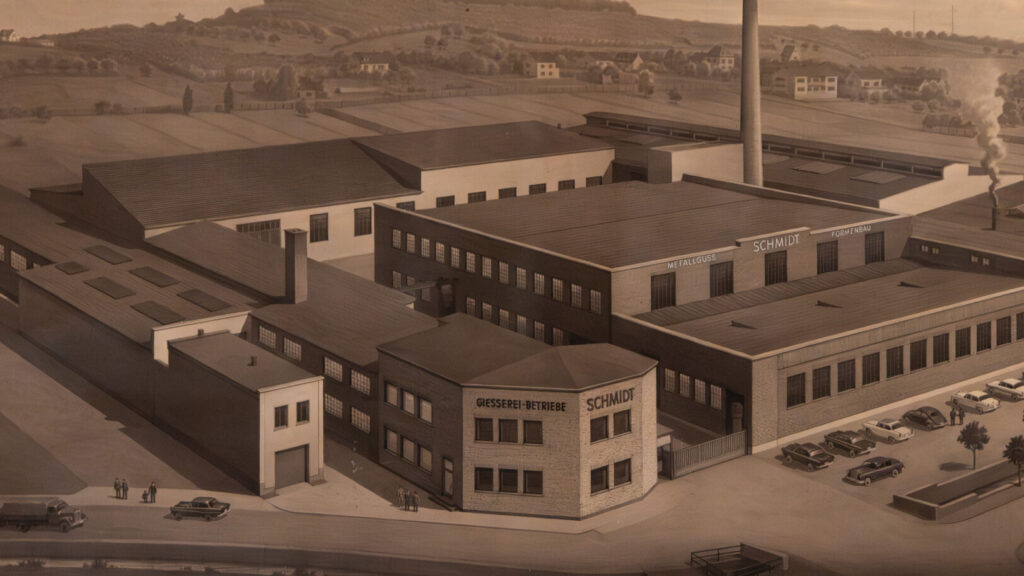

Industrial heritage of the Rhineland – History of our company

Founded in Bonn shortly after World War II, our company looks back on an eventful history full of tradition and innovation.

The company was founded in 1949 by Fritz Schmidt and Gerhard Schwede as a sand casting foundry in Bonn. As early as 1957, the start of die casting production marked the first strategic expansion of the range of services. In the years that followed, the company underwent continuous expansion: in 1964, a centrifugal and heavy metal foundry was acquired in Cologne, followed in 1970 by the acquisition of a die casting foundry in Gelsenkirchen.

Following the death of company founder Fritz Schmidt in 1973, the shareholder structure was reorganized. A major milestone was the planning and construction of the company’s current location in Meckenheim in 1980. From 1983 onwards, activities were gradually concentrated at this location with the relocation of the plants in Bonn and Cologne to Meckenheim.

The continuous expansion of production capacities continued with the extension of the finishing hall in 1987. In 1989, the Gelsenkirchen site was also relocated to Meckenheim. Just one year later, in 1990, another foundry hall was added. In 2004, the sand casting departments were closed and the focus was consistently placed on expanding die casting production. From 2006 onwards, the systematic development of mechanical processing began, further increasing the company’s vertical range of manufacture.

The technical equipment was continuously modernized in the following years, including the purchase of a third die casting machine with a clamping force of over 4,000 tons in 2011 and a 1,400-ton die casting machine with two-plate technology in 2013. In 2015, a continuous washing system was put into operation.

The company also set standards in the area of quality and environmental management: in 2016, it was successfully certified according to ISO/TS 16949, followed in 2018 by certifications according to ISO 14001 and IATF 16949. Also in 2018, the company invested in another die casting machine with a clamping force of 2,200 tons and three-plate technology. In 2020, a new 840-ton die casting machine and two additional machining centers were purchased.

In 2025, there was a change in management. At the same time, extensive investments were made in the technical infrastructure, including two new pre-melting furnaces, three friction stir welding machines, two casting washing systems, seven machining centers, and a new trough belt continuous blasting system.